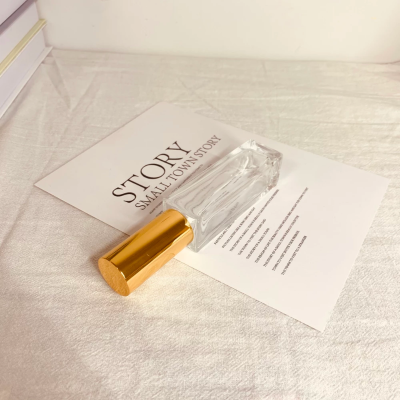

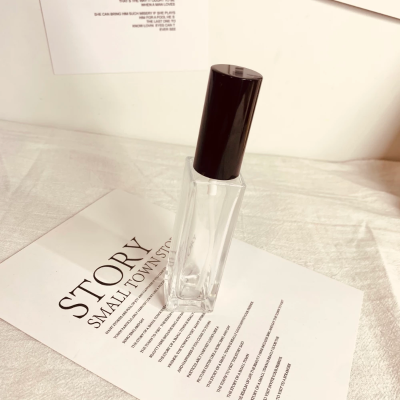

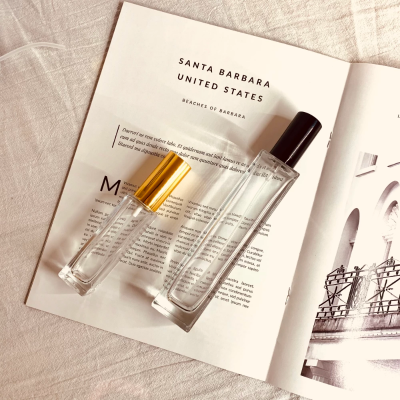

| Product name | Glass Perfume Bottle |

| Material | Glass |

| Capacity | 30ml/50ml/100ml |

| Weight | 20g |

| MOQ | 100pcs |

| Sample | Afford |

| Logo | Customized |

| Printing | Hot stamping,Silk printing,Painting,Thermal Transfer,Engraving,Labeling. |

| Packaging | Carton Box,Pallet |

| Cap color | Customzed Color |

| Sample | Provided Freely |

| Cap color | Customzed Color |

71% of the world’s beer is filled in glass beer bottles, and China is also the country with the highest proportion of glass beer bottles in the world, accounting for 55% of the world’s glass beer bottles, more than 50 billion per year. Glass beer bottles are used as beer packaging. Mainstream packaging, after a century of vicissitudes of beer packaging, is still favored by the beer industry due to its stable material structure, no pollution, and low price. Glass bottle is the preferred packaging when it has the best touch. In general, glass bottle is still the usual packaging for beer companies.” It has made a huge contribution to beer packaging, and most people love to use it. Glass products are made of more than a dozen raw materials such as broken glass, soda ash, sodium nitrate, barium carbonate, quartz sand, etc. A container made by melting and shaping at 1600 degrees high temperature can be produced according to different molds. The glass bottles mainly include all kinds of wine bottles, beverage bottles, pickle bottles, honey bottles, canned bottles, soda bottles, carbonated beverage bottles, coffee bottles, tea cups, 0.5kg/2.5kg/4kg wine jars and other special-shaped glass. bottle,. The glass bottle has a light-tight seal and allows long-term storage of products that are highly sensitive to humidity.

Glass packaging materials and containers have many advantages: glass materials have good barrier properties, which can well prevent the invasion of oxygen and other gases to the contents, and can prevent the volatile components of the contents from volatilizing into the atmosphere; glass bottles It can be used repeatedly, which can reduce the packaging cost; the glass can easily change the color and transparency; the glass bottle is safe and hygienic, has good corrosion resistance and acid corrosion resistance, and is suitable for acidic substances (such as vegetable juice drinks, etc.) In addition, because glass bottles are suitable for the production of automatic filling production lines, the development of automatic glass bottle filling technology and equipment in China is also relatively mature, and the use of glass bottles to package fruit and vegetable juice beverages has certain production advantages in China.